Are you compliant with overhead electrical regulations? When was the last time you looked at the powerlines above your home or business and thought about who ensures they’re safe? For most of us, overhead electrical systems just fade into the background until something goes wrong. But did you know that failing to meet compliance requirements for these systems can result in hefty fines, legal issues, and serious safety risks?

Overhead electrical systems are essential for delivering electricity across towns, cities, farms, and commercial zones. They’re everywhere, but they come with strict rules and technical standards. Why? Because they deal with high-voltage electricity, mistakes can be deadly.

In this article, we’ll walk you through how these systems work, why the regulations exist, the consequences of non-compliance, and what technical elements you need to consider. We’ll also explore common challenges, when underground alternatives make sense, and how Bright Force Electrical can help you stay compliant and safe.

What is Overhead Electrical Systems

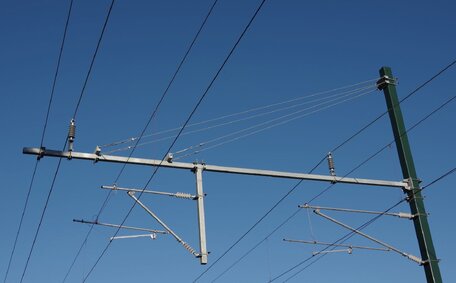

Overhead electrical systems are installations where power cables are strung above the ground, usually suspended from utility poles. They’re a tried-and-true method of electrical distribution, especially in areas where terrain, cost, or accessibility make undergrounding impractical.

A standard setup includes utility poles (often timber or steel), crossarms that support the wires, electrical conductors, and insulators to prevent leakage of electricity. You’ll also find hardware like brackets, clamps, and stay wires to stabilise the entire structure.

These systems are used in a wide range of environments. In residential suburbs, they’re often seen running along property lines or across back lanes. In rural settings, they stretch for kilometres between farms and towns, often facing exposure to wind, storms, and vegetation. In commercial zones, they handle heavier loads and must meet more rigorous standards due to higher energy demand.

![Overhead Electrical Compliance Overhead Electrical Compliance]()

Compared to underground systems, overhead lines are faster to install, easier to inspect, and more cost-effective. However, they’re also more visible, vulnerable to environmental conditions, and require careful ongoing maintenance.

Why Compliance Matters

So, why does overhead compliance matter so much? The answer boils down to three major areas: legal obligations, safety, and long-term liability.

From a legal standpoint, non-compliance can result in fines, stop-work orders, or having to rip out and redo entire installations. If you’re a property owner or a contractor, this can delay projects and cost thousands.

Safety is an even bigger concern. Improperly installed or poorly maintained overhead systems are a serious hazard. They can cause electric shocks, fires, or collapses during storms. Something as simple as wires sagging too low or being too close to a tree can lead to disaster.

And let’s not forget long-term reliability. Insurance companies often require proof that your system is compliant. If an accident occurs and your setup doesn’t meet standards, you could be liable for injury or property damage.

Contractors, electricians, and even homeowners can be held accountable if an overhead system fails. That’s why getting it right the first time—and maintaining it over time—isn’t optional. It’s essential.

Key Regulatory Bodies and Standards in Australia

In Australia, compliance is governed by a patchwork of national and state-based standards, along with oversight from energy providers and regulatory authorities.

At the national level, the AS/NZS 3000 Wiring Rules are the backbone of electrical safety. This standard outlines how systems should be designed, installed, and maintained. It’s updated regularly to reflect emerging risks, new technologies, and lessons from past incidents.

Each state and territory then has its own regulatory body responsible for enforcement:

- Energy Safe Victoria oversees compliance, licensing, and safety education in Victoria.

- NSW Fair Trading handles electrical licensing and enforcement across New South Wales.

- Electrical Safety Office QLD regulates installations and conducts inspections in Queensland.

- Other states, like South Australia and Western Australia, have similar agencies.

Utility providers also play a significant role. Companies like Ausgrid, Endeavour Energy, and Energex have strict service and clearance guidelines. If your installation crosses public property or connects to their network, you’ll likely need to work closely with them and secure permits and approvals.

Legislation can change quickly, especially around issues like bushfire risk or urban development. Keeping up to date with these changes is vital. Permit requirements may vary based on location, type of installation, or proximity to public infrastructure.

Before starting any new installation, relocation, or major upgrade, check which permits and inspections are needed. Missing a step could put your entire project at risk.

Technical Compliance Factors

Now let’s dive into the nitty-gritty—the technical details that inspectors and regulators look for when assessing overhead systems.

Clearances are one of the most scrutinised areas. Lines must maintain minimum distances from buildings, trees, roadways, and other services. These distances are there to prevent accidental contact, sagging, or interference during high winds and storms.

Pole height and spacing must be suitable for the terrain and electrical load. Too close together, and you’re wasting resources. Too far apart, and the wires may sag dangerously. Tensioning is also crucial—too tight and the wires may snap, too loose and they’ll droop.

Conductor and insulation materials need to be chosen carefully. The wrong combination can result in overheating, failure under load, or even arcing. Materials must be weather-resistant and matched to voltage and load requirements.

Overcurrent protection, such as fuses or circuit breakers, ensures the system doesn’t overload and catch fire. Meanwhile, earthing systems help divert dangerous surges, particularly during lightning storms or equipment failure.

Every component must work together to ensure the system is robust, durable, and safe. Inspectors will check this in detail before signing off on a project.

Common Compliance Challenges

Even with the best intentions, meeting compliance requirements can be tricky. Here are some of the most common roadblocks.

Property access is a big one. Easement disputes often arise when overhead lines cross private land. If the proper agreements aren’t in place, projects can stall or result in legal action.

In rural or bushland areas, weather and terrain can throw a spanner in the works. Poles may need to be reinforced or relocated to account for soil type, flood risk, or high winds.

Older systems are another challenge. Many homes and farms still use outdated infrastructure that no longer meets modern standards. Retrofitting these can be expensive and time-consuming, but it is necessary.

Coordination between trades can cause delay, too. Electricians, arborists, civil contractors, and inspectors all have roles to play, and getting everyone on the same page isn’t always easy.

Then there’s the paperwork. Permits, drawings, clearances, and compliance records all need to be filed correctly. Any misstep can delay a project or trigger rework.

Inspection, Maintenance, and Ongoing Responsibilities

Think of compliance as an ongoing process, not a one-time task. Overhead systems need regular inspections, maintenance, and documentation to remain compliant and safe.

Inspection frequency varies. In residential settings, inspections might be needed every few years. In commercial or high-risk zones, checks may be more frequent, especially in areas prone to storms or bushfires.

![Compliance Overhead Electrical Lines Compliance Overhead Electrical Lines]()

A standard inspection covers visual checks (for sagging wires, damage, or corrosion), mechanical integrity (poles, brackets, tension), and electrical performance (load, resistance, grounding). Photos and test readings are often recorded in compliance logs.

After installation, property owners typically take on responsibility for maintenance, especially for lines within private boundaries. This includes scheduling inspections, clearing trees, and ensuring documentation is current.

Licensed electricians are responsible for ensuring that any changes, repairs, or extensions are carried out according to code. Failing to maintain records can lead to insurance claims being denied in the event of an incident.

Underground Alternatives & When They’re Preferable

While overhead systems are common, they’re not always the best option. In certain situations, underground electrical systems offer clear advantages.

In densely populated urban areas, visual clutter and space constraints make undergrounding the preferred choice. Noise reduction, aesthetic improvement, and reduced fire risk also make it attractive in residential developments and commercial precincts.

In bushfire-prone zones, overhead systems can be a hazard. Falling branches, extreme winds, and dry vegetation all increase the risk. Undergrounding mitigates much of that danger.

It’s also ideal where councils or utility providers prohibit overhead lines—often in heritage areas, scenic landscapes, or environmentally sensitive zones.

Of course, underground installations are more complex. They require trenching, soil assessment, and more rigorous waterproofing. But with fewer visual and environmental impacts, they’re often worth the investment.

Bright Force Electrical offers both overhead and underground services, giving you the flexibility to choose what’s best for your property and budget.

Keep Your Power Flowing Safely – Talk to the Experts

Staying compliant with overhead electrical standards isn’t just good practice—it’s a legal and safety necessity. Whether you’re installing a new system, upgrading an old one, or just want to make sure everything’s above board, getting professional advice can save you time, money, and a whole lot of stress.

At Bright Force Electrical, our experienced, fully licensed electricians know the ins and outs of both overhead and underground systems. We handle everything—from permits and inspections to repairs and new installations.

We’ll work with you to understand your site, recommend the safest and most compliant options, and make sure your power keeps flowing without a hitch.

Get in touch today for an on-site inspection or a personalised compliance check. Your safety and peace of mind are just a call away.