Ever wondered how long those power lines, either stretching across your street or buried beneath your driveway, actually last? Most of us don’t give them a second thought... until there’s a blackout or a storm sends one crashing down. But given the wild swings in Australian weather, knowing how long your power infrastructure will hold up is more important than you might think.

From salty coastal breezes to bushfire heatwaves and sudden storms, our conditions put serious stress on power lines. And the way they’re built, along with how they’re maintained, can mean the difference between decades of reliable service or constant headaches.

In this guide, we’ll break down what really affects the lifespan of power lines, compare overhead and underground setups, look at costs, and help you figure out which system is more likely to go the distance. Let’s lift the lid on the wires that keep everything running.

What Influences the Lifespan of Power Lines?

So, what actually determines how long a power line will last? Turns out, it’s not just about what it’s made of. The environment, workmanship, and ongoing maintenance all have their say.

Coastal areas are tough on gear. Salty air quietly eats away at metal components, corroding them over time. Inland, you’ve got searing heat and fire risk. And then there are the storms, strong winds can whip cables around, trees can come down, and excess moisture sneaks into weak points and causes long-term damage.

Materials matter too. High-quality aluminium or copper, thick insulation, and weather-resistant parts all help cables go the distance. But if the job’s rushed or budget cuts lead to cheaper components, you’re probably looking at earlier replacements.

And let’s not forget about access. If maintenance crews struggle to get to your lines, or worse, don’t check them at all, small faults can quietly grow into expensive failures. Regular inspections and quick fixes are key to extending a line’s working life.

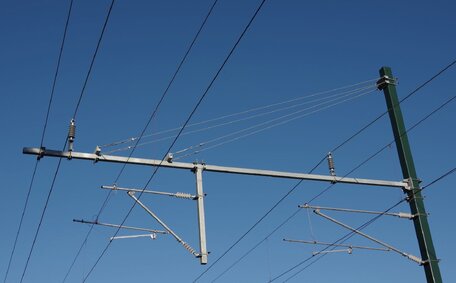

Lifespan of Overhead Power Lines

![Overhead Power Lines Professional Overhead Power Lines Professional]()

Overhead power lines are everywhere. They’re what most of us picture when we think about power delivery: wires strung between tall poles, standing guard along roads and across paddocks. These lines usually feature aluminium or copper wires, mounted on timber or concrete poles that brave the elements day in, day out.

On average, overhead lines canlast between 30 and 50 years, but that depends on where they’re installed and how they’re looked after. Trees nearby? That means branches snapping in storms. Too much sun? UV rays degrade cable sheathing. Add in wind stress, and the wear starts to add up.

Maintenance can be a real mission, too. Poles in rural or bushy spots aren’t always easy to reach, and damage from rot, termites, or corrosion often goes unnoticed until something fails. Still, they remain a go-to for many projects because they’re quick and affordable to put in place.

Lifespan of Underground Power Lines

![Underground Powerlines Green Boy Underground Powerlines Green Boy]()

Underground power lines are a bit like the quiet achievers of the electricity world. You won’t see them, but they’re working hard under footpaths, driveways, and paddocks, doing their job without drawing attention.

These cables are usually laid in protective conduits or direct-buried in trenches. The materials used like XLPE (cross-linked polyethylene) or HDPE (high-density polyethylene) are built tough to resist moisture, pressure, and soil movement.

Because they’re out of the sun and away from falling branches or fire risk, underground lines tend to last longer, often 40 to 70 years. That doesn’t mean they’re immune to problems. Water can still sneak in if the drainage isn’t up to scratch, and root systems or shifting soil can create issues. And if repairs are needed? You’re digging literally.

But for areas that demand reliability, like hospitals, schools, or new housing estates, the added protection and longer lifespan are often well worth it.

Cost vs Longevity: Is Longer Always Better?

Let’s talk dollars. Overhead power lines are cheaper to install. The materials are more affordable, the process is faster, and you don’t need to dig trenches or worry about soil types. For smaller projects or areas with tight budgets, they make a lot of sense.

But the long-term picture tells a different story. Overhead systems need more frequent maintenance. They’re more exposed to the elements, more prone to damage, and often more expensive to keep running smoothly over time.

Underground lines, by contrast, are a bigger investment up front. Depending on the site, installation costs can be double or more. But they tend to cost less to maintain, experience fewer faults, and add visual and functional appeal to properties.

For developers or councils thinking long-term, that upfront spend often works out as better value especially in areas where reliability and resilience are key.

Safety and Reliability Considerations

![Using Tools Overhead Power Lines Tools Overhead Power Lines]()

When it comes to safety, underground lines have a clear edge. They’re safely tucked away, which means they’re far less likely to be involved in incidents during bushfires, floods, or high winds. There’s also a much lower risk of someone coming into accidental contact with a live wire.

Overhead lines, on the other hand, are exposed to just about everything. Fires can melt them. Trees can bring them down. And when they’re damaged, the risk to people and property can be significant.

In terms of reliability, underground systems again come out ahead. They’re less likely to experience service interruptions from environmental causes. But when something does go wrong, it can take longer to fix. That’s the trade-off—fewer faults, but trickier repairs.

Future-Proofing Infrastructure in Australia

The way we build our cities and suburbs is changing fast. As we plan smarter neighbourhoods and invest in modern infrastructure, underground power is fast becoming the go-to option.

It’s not just about looking tidy, though that helps. Underground lines work better with smart grids, solar connections, and battery storage. They’re also more in line with sustainability goals and urban planning strategies focused on resilience and reliability.

In many new developments, especially around major cities, underground power isn’t just preferred it’s expected.

Which Power Line Stands the Test of Time?

There’s no one-size-fits-all winner here. It really comes down to where you are, what you need, and how long you want the system to last.

Overhead lines are still a great fit for rural or budget-conscious projects. They’re easy to fix, fast to install, and cost-effective, at least in the short term.

Underground lines, while more expensive up front, tend to offer better reliability, fewer outages, and a longer lifespan. For urban, fire-prone, or high-value areas, they’re often the smarter long-term choice.

Thinking Long-Term with Your Power Supply

Power lines might not be the most exciting part of your project, but getting them right can save you big in the future. Whether you’re building, renovating, or managing infrastructure, investing in the right type of power line means fewer headaches and better outcomes down the track.

At Bright Force Electrical, we know what it takes to build systems that last. Our team an expert in Underground Service Lines, and we tailor every solution to suit the conditions and demands of each job. No generic installs here, just quality work designed to go the distance.

If you’re weighing up your options or ready to future-proof your property, give us a call today. We’ll help you choose the right setup, get it installed properly, and make sure your power stays on when it matters most.