A circuit breaker plays a crucial role as a safety device in residential, commercial, and industrial electrical systems. Its main job is to protect electric circuits and spot any potential overloads or short circuits. When it trips, the circuit breaker opens its internal switch, halting the power flow to prevent damage, sparks, or even a fire from happening further down the line.

In this article, we’ll look into how long different circuit breaker models typically last for both homeowners and business owners. Knowing what affects lifespan is key for planning maintenance and budgeting for replacements. We’ll cover the factors that can both extend and shorten the number of years a breaker effectively performs its protective role before it’s time for a replacement.

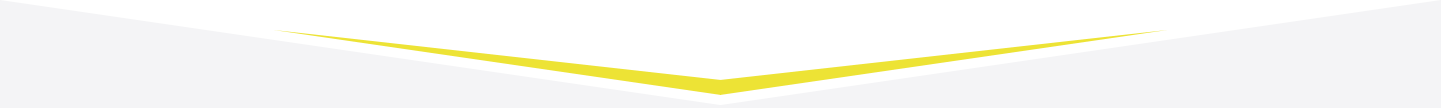

What is a Circuit Breaker?

A circuit breaker is an automatically operated electrical switch designed to protect an electrical circuit from damage caused by excess current from overloads or shorter circuits. When a circuit breaker detects high current flow, it rapidly opens the circuit, interrupting the electrical current.

![2024 04 Circuit Breaker Sitting On Bench Circuit Breaker Sitting Bench]()

There are different types of circuit breakers used in homes and businesses. Residential applications generally use single-pole or dual-pole circuit breakers in the main electrical panel to control individual 120/240V circuits. Larger multi-pole breakers may control high-amperage appliances or subpanels.

Commercial and industrial facilities require more robust breakers tailored to their specific power needs, ranging from small to large frame styles. Moulded case, insulated case, and power air circuit breakers are commonly used in these settings. It’s crucial to understand the right application and specifications to ensure safety and adhere to codes.

What Affects A Circuit Breaker’s Lifespan?

Internal Factors

Excessive heat within a circuit breaker panel can greatly affect its lifespan. High ambient temperatures mean the breaker has to dissipate more heat produced during electrical arcs, speeding up wear and tear. Internal parts, like the spring mechanism, may lose their elasticity more quickly under such conditions. Nearby machinery vibrations can also hasten the degradation of these components.

External Factors

Environmental conditions like extreme humidity can cause moisture to penetrate the circuit breaker panel, leading to corrosion. This weakens the breaker and can cause it to fail prematurely. Frequent and significant load changes, such as those from machinery starting and stopping, increase thermal and mechanical stress. These fluctuations can reduce the lifespan of circuit breakers typically designed for stable electrical conditions.

Manufacturing Quality

The longevity of a circuit breaker largely hinges on its manufacturing quality. High-quality breakers are usually built with superior materials, feature corrosion-resistant coatings, and offer stronger breaking capacity. On the flip side, cheaper models tend to miss out on these benefits, making them prone to early failure and less reliable, particularly in demanding environments.

Maintenance and Inspection

Proper maintenance and regular inspections are vital to extending a breaker’s service life. Identifying and addressing minor issues early helps prevent costly failures. A well-maintained circuit breaker panel ensures the system operates smoothly, reducing the risk of a circuit breaker failing unexpectedly.

Estimated Lifespans

![2024 04 Circuit Breakers In A Line Circuit Breakers Line]()

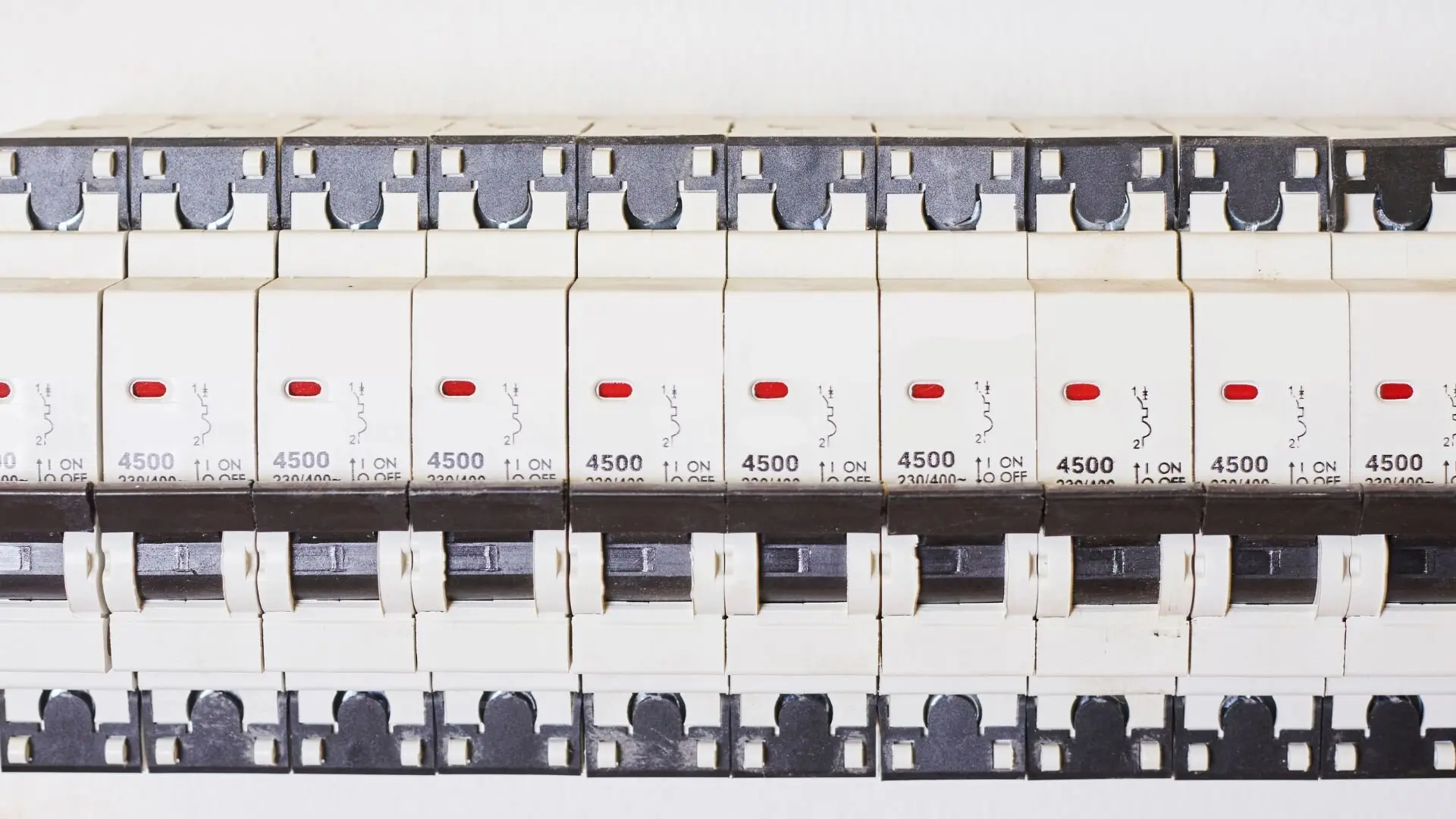

Circuit breakers last for varying durations depending on their environment and application. Their life expectancy can be extended with proper care and attention.

Residential Applications

Residential-grade circuit breakers last around 15-20 years under typical conditions. Those installed in air-conditioned spaces or with minimal continuous loads often reach the upper range of this life expectancy. Regular maintenance can ensure consistent performance and help avoid issues like frequent tripping.

Commercial Applications

Medium-duty breakers used in commercial settings like offices generally last around 12 to 18 years. These breakers are subjected to more variable loads and less controlled temperatures, which can speed up wear. This makes regular maintenance essential in environments with demanding electrical equipment to keep them reliable.

Industrial Applications

Heavy-duty breakers used for industrial electrical equipment like machinery or freezers generally last 8-15 years. High vibration or constant exposure to moisture can reduce their lifespan further, sometimes to under a decade. Proper sizing and regular maintenance help manage thermal and mechanical stresses.

Variances by Breaker Class

Due to their superior construction, high-end modular breakers with advanced features often have a longer life expectancy. Consumer-grade circuit breakers last less and typically reach the lower range of durability. Older models also tend to wear out faster compared to modern designs.

Extending Circuit Breaker Life

- Regular load testing and inspection: Licensed electricians can perform IR scans and conduct tests to verify that trip thresholds haven’t drifted outside calibration tolerances. This detects subtle issues impeding full-rated performance.

- Thermal imaging checks: Using cameras detects loose or overheated connections at risk of starting fires. These "hot spots" cause breakers to see excess heat when nearby.

- Exercise cycling: Manually toggling breakers on/off quarterly like a fire drill spreads apart internal switching contacts and lubricates moving parts for better operation.

- Cold equipment shutdowns: For heavy industrial circuits, scheduled winter downtimes alleviate constant high loads and associated thermal stresses for circuit breakers.

- Early replacement of failing units: Rather than run until failure, swapping out breakers exhibiting any signs of wear preemptively avoids unexpected downtime and costly repairs from destroyed downstream devices if trips are delayed.

- Considering more durable Premium Class breakers: For critical circuits, higher-end breakers with stabler tripping thresholds better withstand extreme conditions and offer the greatest protection over long runs.

Outsourcing to licensed professionals allows leveraging specialised equipment and expert knowledge to maximise the expected lifespan according to code and application needs through proactive maintenance schedules.

Signs of Aging

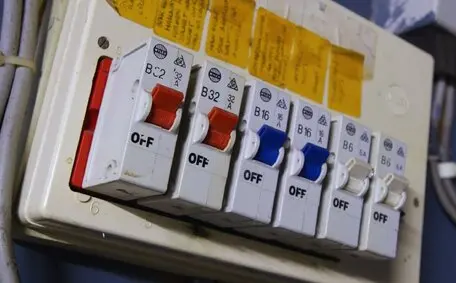

![2024 04 Flicked Circuit Breaker Flicked Circuit Breaker]()

Slowed tripping response

If a breaker doesn’t shut off power as fast as when new, heat building inside could lead to fire risk. Thermal/mechanical wear impedes action.

Pitting or cracking of the breaker case

Water intrusion or gases from extreme arcing corrode the exterior, as found during visual inspections.

Nuisance tripping

Without cause, such as deterioration of the spring mechanism or contact fusion, breakers will keep shutting off even at nominal loads.

Loose connections

Overheating at screw terminals or busbars can melt away holding power. Found by inspection or IR scans catching hot spots.

Abnormal noises or vibration

Breakers in distress may develop noise during opening/closing from degraded insulating materials or bearings.

Change in trip characteristics

Monitoring breaker performance over time helps identify equipment drift beyond safe operating zones.

Scarring/damage to contacts

Prolonged arcing over the contacts erodes precious contact surfaces and reduces holding capacity.

Watching for these kinds of signs warns whether protective capacities are degrading so maintenance can address declining performance ahead of potential failure.

When to Replace

Circuit breakers that show any signs of wear, damage, or deterioration should be scheduled for replacement. Even if a breaker hasn’t outright failed, its components will have degraded performance over time.

Once a breaker reaches the end of its estimated lifespan, replacement is prudent. Using worn equipment risks safety, damaged property, and potential liability from circuit failure. Regular protective device audits help pinpoint when replacement is needed.

It’s false economy to avoid swapping out a tired breaker, as the potential costs of fires or equipment damage far outweigh replacement parts and labour. Preventative maintenance keeps systems safe and functioning properly.

Maintain System Reliability

Establishing an ongoing partnership with a licensed electrical contractor ensures critical infrastructure, such as circuit breakers, receives preventative maintenance checks according to the code.

Professional inspections and scheduled component replacements keep vulnerability levels low by maintaining up-to-date safety equipment. This establishes a cost-effective program tailored to a building or organisation’s individual needs, maintaining peak performance and reliability of electrical systems. For questions about circuit breaker assessments, replacement services or emergency response, contact Bright Force Electrical for a free consultation.