Circuit breakers are indispensable electrical equipment that safeguards homes, businesses, and other facilities from electrical hazards. Acting as the first line of defence, these vital components trip and disconnect power whenever an electrical system encounters overloads, short circuits, or ground faults. This prevents fire damage to electrical devices and appliances and ensures the safety of occupants.

Regular testing of circuit breakers is essential to ensure they work correctly and meet strict safety regulations. Skipping regular checks can have serious consequences, as faulty circuit breakers might not trip when needed during electrical problems, putting the whole system at risk. Whether it’s for new installations or existing setups, figuring out how often to test is key to keeping things safe and reliable.

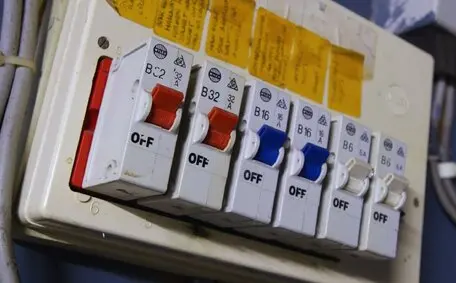

What Is A Circuit Breaker?

Circuit breakers are essential components in residential and commercial electrical systems, designed to automatically interrupt the flow of electricity when a fault or overload is detected. Their primary purpose is to protect electrical appliances, wiring, and people from the hazards of excessive electrical currents, which can lead to fires, shocks, and equipment damage.

Various types of circuit breakers are designed for specific purposes. Standard ones deal with overloads and short circuits. Ground fault circuit interrupters (GFCIs) keep you safe from electric shocks by stopping ground faults, while arc fault circuit interrupters (AFCIs) help prevent fires by catching electrical arcing.

![2024 04 Four Circuit Breakers Circuit Breakers]()

Most of today’s circuit breakers designed for simple protection functions in final distribution applications are non-adjustable, so they do not require any unique configuration. However, circuit breakers intended for LV applications above 100A in main switchboards – i.e., moulded case circuit breakers (MCCB) and air circuit breakers (ACB) – typically integrate protection for many fault conditions, like overload, short circuit, and earth fault.

Faulty or malfunctioning circuit breakers can have severe consequences. Suppose a breaker fails to trip during an overload or short circuit. In that case, the excessive current can potentially cause electrical fires, damage connected appliances, and even pose a risk of electric shocks to individuals. Additionally, breakers with high contact resistance or those exposed to low voltage conditions may not operate as intended, necessitating more frequent testing and maintenance services to ensure proper functionality.

Regular testing of circuit breakers is key to spotting problems early and ensuring they work as they should when needed. Skipping these checks can have serious consequences, so following the suggested testing schedules is vital for keeping the electrical system safe and reliable.

What Affects Testing Frequency

Age of Components

Older electrical systems and circuit breakers may require more frequent electrical tests due to the natural wear and tear that occurs over time. As components age, their ability to protect an electrical circuit against faults diminishes. Regular circuit breaker testing helps ensure each circuit breaker operates correctly, especially in systems involving molded case circuit breakers or low voltage breakers, which are commonly used in residential and commercial setups.

Usage and Load

Usage and load also play a significant role in determining testing intervals. Systems with heavier demand on lighting circuits or power supply infrastructure are exposed to increased electrical stress. This can accelerate wear on electrical installations, prompting the need for routine circuit breaker testing and assessments such as a contact resistance test, timing test, or insulation resistance test to identify any performance concerns.

Environmental Conditions

Environmental conditions can affect the internal components of circuit breakers. In regions with extreme temperatures or corrosive atmospheres, regular visual inspection and testing are necessary. Such inspections should accompany electrical repairs when deterioration is found and may include primary injection testing or secondary injection testing as part of the diagnostic process.

Manufacturer Recommendations

Manufacturers provide specific guidelines for testing molded case circuit breakers and other units used in electrical installation systems. These recommendations often include periodic timing tests, contact resistance tests, and functional assessments to ensure the circuit breaker operates within expected parameters.

Local Codes and Regulations

Local codes and regulations, particularly for new electrical installations in industrial or commercial facilities, may require scheduled circuit breaker testing. These codes ensure all electrical installations meet safety standards and that devices like low voltage breakers continue to protect lighting circuits, outlets, and other parts of the electrical circuit.

Recommended Testing Intervals

In residential settings, it’s usually recommended to conduct circuit breaker testing once or twice a year. This practice keeps your power supply reliable and appliances operating safely.

Commercial and industrial facilities often require more frequent testing. Many experts recommend performing tests such as primary injection testing, secondary injection testing, and insulation resistance tests every six months—or quarterly—depending on the system’s criticality and load demands.

![2024 04 Testing Tripping On Circuit Breakers Testing Tripping Circuit Breakers]()

In high-dependency environments like hospitals or data centres, even monthly or weekly tests may be necessary. These facilities depend on a consistent power supply, and any fault in the electrical circuit could have serious consequences.

To complement these tests, regular visual inspection of circuit breakers is essential. This helps detect corrosion, physical damage, or signs of failure not captured through routine functional tests.In all settings, adhering to the recommended testing intervals—while incorporating visual inspections, electrical repairs, and advanced diagnostics like timing tests—ensures that circuit breaker testing is comprehensive and effective. This integrated approach is key to maintaining safe and functional electrical installations across homes, businesses, and critical infrastructure.

Stay Safe and Compliant

To ensure your electrical systems’ reliability and safety, seek Bright Force Electrical’s expertise. Our team of professionals is dedicated to providing comprehensive circuit breaker testing and maintenance services.

With extensive knowledge and experience, we can assess the condition of your circuit breakers, perform thorough inspections, and identify any potential issues before they escalate. Trust Bright Force Electrical to support your electrical needs, prioritising compliance with industry standards and regulations by contacting us. Our unwavering commitment to electrical safety and reliable power point operation ensures peace of mind and property protection.